描述

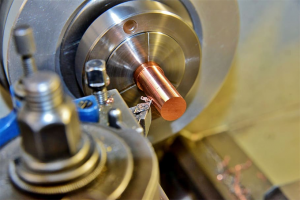

5-Axis CNC Machining

GX Proto 5-axis machining is the use of computer numerical control (CNC) to simultaneously move a cutting tool or part along five axes. The cutting tool moves continuously along each axis so the tip is always perpendicular to the part. This process can be applied to any complex part.

The general tolerance can reach ±0.01mm, and the programmers of GX Proto can control the best tolerance of five-axis CNC to ±0.0025mm.

5-axis CNC machining in USAGE

5-axis CNC is generally used for high-precision products or very complex and large-volume products.

Of course, we can also use 3-axis CNC to achieve this, but considering labor cost and time costs, sometimes 5-axis CNC is more cost-effective.

Five-axis machining is often used in pharmaceutical, military, aerospace, petrochemical, and other fields. The five-axis machine tool can process different sides of the workpiece without changing this cost, the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

5-axis used in Aviation and Aerospace

5-Axis CNC is often used in the aerospace field to process airframe parts, the precision required by the aerospace industry for aircraft, rockets, satellites, etc. can directly impact the safety of operators.

And it’s mostly used in turbine parts, impellers with free-form surfaces, etc

Poorly made parts on a flying machine could prevent the system from working properly, leading to a manufacturing defect that could lead to a crash. That’s why we need to use the 5-axis to control tolerance well and control the safety

Poorly made parts on a flying machine could prevent the system from working properly, leading to a manufacturing defect that could lead to a crash. That’s why we need to use the 5-axis to control tolerance well and control the safety

5-axis used in pharmaceutical(Medical Devices)

Medical components and tools require designs that are precise enough to ensure that components used for surgery or replacement parts fit perfectly. Improper cuts or imperfect edges can render medical supplies unusable. This makes five-axis machining the preferred way to create custom medical tools and components.

5-axis used in Automotive

Modern cars are equal parts of an electronic and mechanical marvel. To ensure the correct fit of the mechanical parts, a five-axis machine can be used. Also, smaller electrical enclosures and other components may require the use of 5-axis CNC machines.

5-axis used in Architecture

Architectural designs are essentially giant puzzles in which the pieces must fit together perfectly. A small mistake in the cutting of a component can make a building’s design so far from its original intent that it fails inspection. Door frames are one of the building components that may require five-axis machining to create.

While five-axis CNC machines are useful for the above applications, some of these can be achieved using a three-axis machine and a suitable operator who is good at positioning material and moving it to create cuts in different axes.

Whenever you need to create a custom part, choosing to use a three-axis machine with trained experts offers a variety of options to save money.

This is the service that GX Proto can provide. Use 3-axis CNC to complete 5-axis CNC products as much as possible, thereby reducing your cost