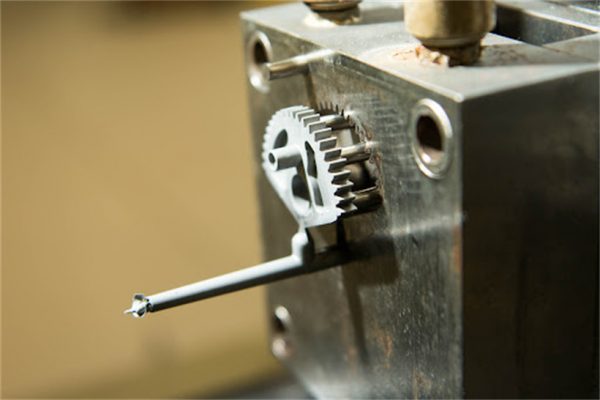

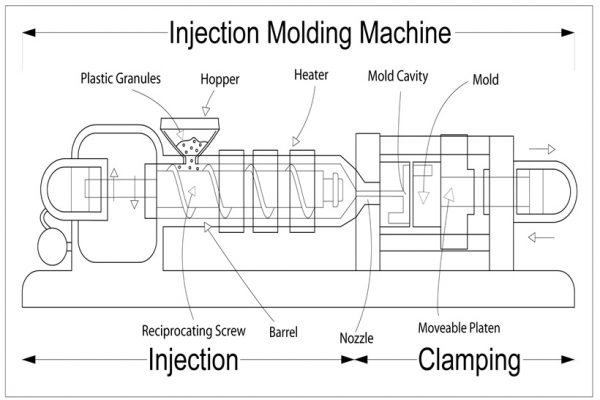

Metal injection molding (MIM) is a metalworking process in which finely-powdered metal is mixed with binder material to create a “feedstock” that is then shaped and solidified using injection molding.

The molding process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder (debinding) and densify the powders. Finished products are small components used in many industries and applications.

Due to current equipment limitations, products must be molded using quantities of 100 grams or less per “shot” into the mold. This shot can be distributed into multiple cavities, making MIM cost-effective for small, intricate, high-volume products, which would otherwise be expensive to produce.