Plastics Low-Volume, we usually use 3D Printing, Vacuum casting, Rapid Injection Molding to achieve this demand.

The main limiting factors of 3D printing are the material choices and potential for different surface finishes. Also, if you are producing large quantities of the same part, other processes may offer cost advantages.

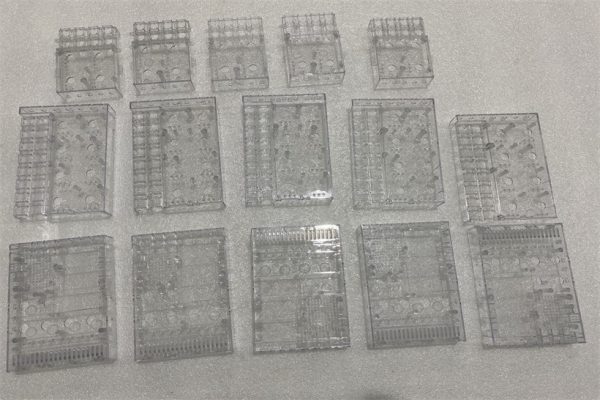

Vacuum casting is a quick option for low volumes of parts, but because of the labor involved, if part numbers start climbing above 50 pieces, the cost and lead time will start climbing, too.

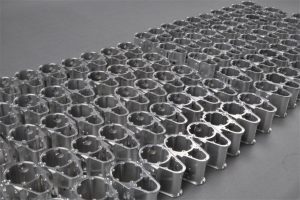

Rapid injection molding is essentially the same as injection molding for production with a lower initial investment. It is a great option if you are expecting low- to mid-volume demand for parts, up to about 50,000 pieces per year.

These are some of the options for low-volume plastic parts production. Choosing one that best fits your project depends on a lot of different factors, and it may be helpful to consult with a specialist before making a final decision.