CNC manufacturing is a subtractive process that starts with our machinists programming our machining centers directly from your CAD files.

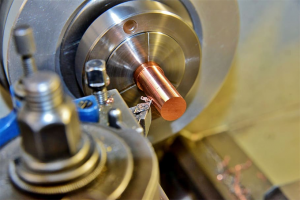

Our machining centers use tools of varying sizes and shapes to remove material from a solid block of metal or plastic to reveal your part shape. In the case of large or highly complex parts, GX Proto will use CNC manufacturing to make “fabricated” parts where a part is sectioned in the CAD file, machined in these sections, and then our craftspeople bond the sections back together to form your completed part.

Machined parts from CNC prototyping are durable, produced in production materials, highly accurate, and have a superb surface finish. These parts can be painted or polished to create highly cosmetic or clear prototype through production use parts.

Materials:

Plastics: ABS, PP, PC, POM, ABS+PC, HDPE,PEEK,PMMA,PTFE, Carbon fiber etc…

Metallic: Aluminum, Brass, Copper, Stainless Steel, Titanium, Tungsten Steel, Carbon Steel, etc…